Linear

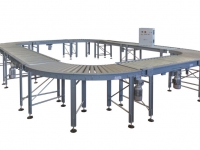

The Mancini Solutions produces motorized roller conveyors for transport different kinds of products.

The motorized indle conveyor are made according to specific customer requirements and in fully respecting the laws on safety at work and in accordance with the CE Machinery Directive. The size and design and all technical specifications, can be agreed with the client in the estimate. They are built with a sturdy frame made of galvanized sheet, or customizable and epoxy coated. The conveyors curves are supplied with adjustable supports, also according to customer requirements.

- With chain transmission tangential, with friction or motorized rollers

- With toothed belt transmission, with friction or motorized rollers

- With toothed belt (round or flat) trasmission

- Completely in stainless steel AISI 304

MOTORIZED OR FRICTION CONVEYOR WITH CHAIN TRASMISSION

Motorized roller conveyors with chain are made with a robust frame of galvanized steel or customized with epoxy dusts . These roller conveyors are well suited to carry medium to heavy weights. Motion transmission is due to a tangential chain.

Motorized roller conveyors with chain are made with a robust frame of galvanized steel or customized with epoxy dusts . These roller conveyors are well suited to carry medium to heavy weights. Motion transmission is due to a tangential chain.

AVAILABLE IN DIFFERENT VERSIONS

- With friction rollers

- With motorized rollers

- Completely in stainless steel AISI 304

GENERAL FEATURES

- Supporting side in metal sheet cut and bent with Cnc

- Galvanized steel frame or powder coated

- Rollers in galvanized steel Ø 50-60-76 (mm)

- Welded tubular supports with adjustable supports

- Motion conveyed through chain rings or tangential chain

- All the components are treated with galvanization

- The principal moving parts (rollers excluded) are protected with a carter

- Motor’s and adapter’s size depend on the use

- Standard widths: 400-500-600-700-800-900-1000 (mm)

- Standard lengths: 500-1000-1500-2000 (mm), with the possibility of combination

OPTIONAL

- Electrical panel with PLC

- Electrical panel with motor protection (start / stop and emergency)

- Block pack at the end, fixed or pneumatic

- Spintore pneumatico o elettronico

- Deviatore ortogonale a 90° a cinghie

- Double motorizzation

- Wheels with brakes, Connecting plates, Fixed or adjustabl sides

FRICTION CONVEYOR WITH FLAT BELT

The motorized rollers conveyors with flat belt, find their use in the transport of products with a maximum weight of 30Kg, this model of conveyors can be completely integrated with the idler rollers of the series RLF, the transmission of motion takes place via a flat belt ring, which allows the locking of the product without recarne the rubbing with the roller.

The motorized rollers conveyors with flat belt, find their use in the transport of products with a maximum weight of 30Kg, this model of conveyors can be completely integrated with the idler rollers of the series RLF, the transmission of motion takes place via a flat belt ring, which allows the locking of the product without recarne the rubbing with the roller.

AVAILABLE IN DIFFERENT VERSIONS

- Standard widths – standard lengths – standard heights

- With friction rollers Ø 32 o 50 (mm)

-

- Completely in stainless steel AISI 304

GENERAL FEATURES

- Galvanized steel frame or powder coated

- Supporting side in metal sheet cut and bent with Cnc

- Rollers in galvanized steel Ø 50-60-76 (mm)

- Motion conveyed through flat belt

- All the components are treated with galvanization

- The principal moving parts (rollers excluded) are protected with a carter

- Motor Power 0,18 (K)w

- Standard widths: 400-500-600-700-800 (mm)

- Standard lengths: 500-1000-1500-2000 (mm), with the possibility of combination

- Standard heights: 550-750 / 660-1000 / 770-1200 (mm)

ORTHOGONAL DIVERTER 90° WITH BELTS

Made with a motorized roller conveyor and belts inserted transversely to the rollers. When the product arrives on the diverter, the rollers stop, the belts are raised pneumatically and then rotates of 90°, putting the product on a conveyor.

45° ROLLER CONVEYOR FOR LATERAL ENTRANCE

This 45° roller conveyor allows the entrance of products from secondary lateral lines into the main line. The wheel at the edge allows for the rotation of the pack.

WIDTHS: 400-500-600-700-800 (mm)